In the previous Desk Diary, we took a look at the transition of how we went from working out of my house for a few years to finally getting our own proper office.

Today, I still look around the office and reminisce at how we managed to startup in such a small place.

Desk Diary 20150228

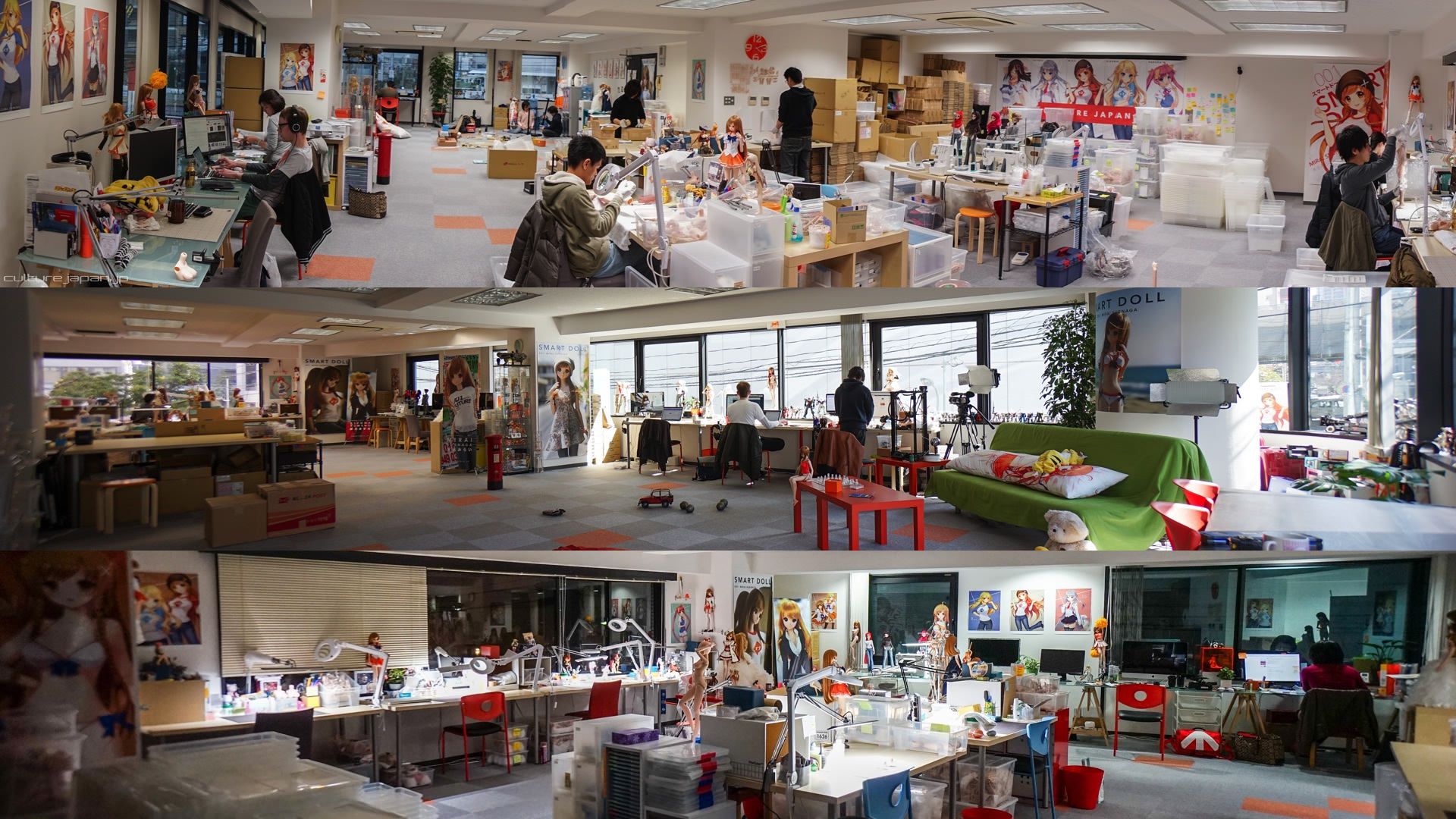

Since the last time we spoke, I moved desks into the lounge area that I said I wanted to keep clear of workstations - but it seems that we are growing at a pace way faster than I imagined and need to use up as much space as we can before we move office again which is could even be later this year at the rate we are growing.

Of late, I've been preoccupied with working out how to scale the Smart Doll production line while maintaining quality, keeping costs low, sourcing for new vendors, removing bottlenecks and up until recently finding staff was a problem too - until I realized that the solution was to do more photowalks.

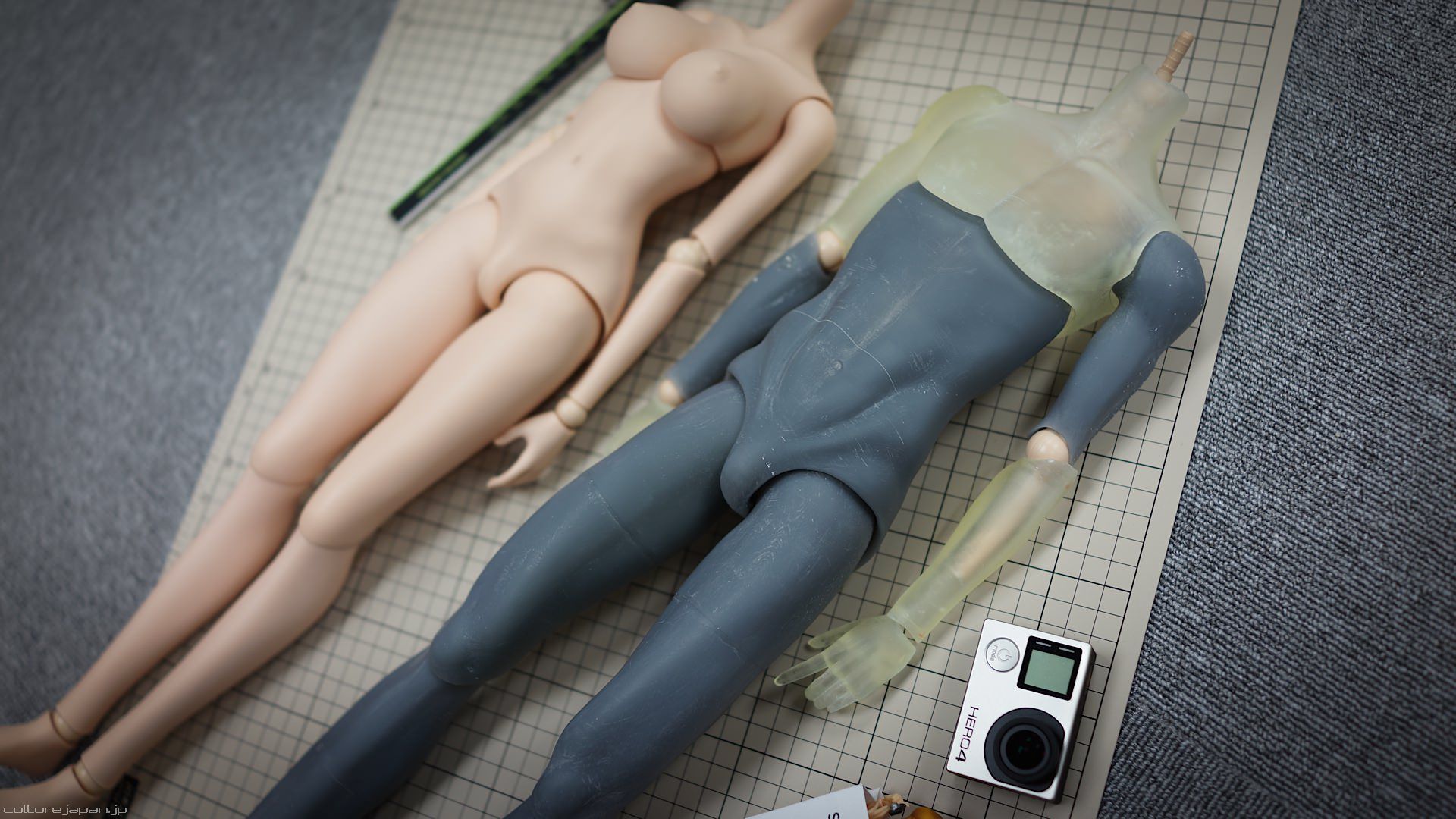

Scaling the production line means to introduce new processes which in turn introduces new problems. I've just created a set of Mass Production slush casting molds which should enable us to make more parts - but because they are new molds, we need to start all over again in learning how to use them.

The new molds have different wall thicknesses and are placed at different angles to accommodate more parts which means they need to be placed in a different position when on the centrifugal unit for example.

Wifey and I went back to IKEA for the zillionth time to get more tables and storage for the new office layout. One of the great thing about having more warm bodies in the office is that the furniture gets put together in a jiffy ^^

My previous desk with Mirai displayed on the Smart Air Stand - it allows Smart Doll to be displayed mid air without a saddle or "C" shape grasp around the waist which would leave Smart Doll looking not-so-smart ><

In the middle of moving my stuff over to the other side. As usual, after I moved everything I needed to my new spot, I discovered a bunch of cables left over that were not attached to anything ^^

While I liked the IKEA glass tables that I used since 2007, there is something that I like about these wooden ones - for some reason I feel that they are more suitable for our workspaces. They are also 3 times cheaper than the glass ones and so much more lighter and easier to move around.

I dont like the typical office chair that rolls around - they are way too bulky and not even comfortable to sit in which is why I stuck to the four legged ones - which are also cheap too ^^

There is more sunlight on this side of the office but the sun beams in during the mornings - good thing the office comes with blinds.

My main machine is now a MacBook Retina. Fonts look great but everything else looks crap - its extremely difficult to do graphic work for web or print which is why I use an external monitor.

My main machine is now a MacBook Retina. Fonts look great but everything else looks crap - its extremely difficult to do graphic work for web or print which is why I use an external monitor.

All our work for print must be checked on an external display when using a Retina machine.

Picked up the U2414H Dell UltraSharp 24" Monitor which has been great so far. You will see reviews by folks having difficulty connecting it for the first time - the solution is to simply not use the Display Port cable that came with it.

Smart Doll Kizuna Yumeno - so smexy and cute! ><

Folks who want one can get in the pre-order waiting list.

Folks who want one can get in the pre-order waiting list.

Currently using the Xperia Z2 - still waiting for Lollipop so that I can save stuff on the SD card again ><

The "waterproof" seal for the Micro USB port keeps popping out as you see in the photo though.

The "waterproof" seal for the Micro USB port keeps popping out as you see in the photo though.

The Xperia series is the only flavor of Android where I don't need to change the OS to CyanogenMod.

This figure of Alisa Ilinichina Amiella by Alphamax is so gorgeous! Booty so cute! Figures go well with plants - I removed the base and have now have Alisa guarding my greenery.

Folks interested in Alisa (or any of the figures below) can look for her on one of the trusted online retailers listed below.

Kongo: Half-Damage ver by Max Factory - I like the tag line - "The precious equipment I got from the admiral... it's ruined!"

How many of you playing Kan Colle?

I'm waiting for the Vita version.

I'm waiting for the Vita version.

Motokooooooo figma by Max Factory.

We filming Culture Japan Season 3 now - using the Sony VG30 and Sony A7 II with FE 35mm (F2.8) and FE 24-70mm (F4) lenses.

I also switched shaver brand to Panasonic after using Phillips for many years. Decided to try out the Panasonic ES-ST27-R and was surprised at how much better these straight blades perform over the rounded ones.

And this is what my desk looks like in the evenings. I still use the same technique when I was using glass tables to have light below the desk - this illuminates the dark area under the table which makes this corner look more roomier.

This is what it looks like to the right of my desk. The windows on the far side of the office face a river.

The same angle by night.

Deep concentration. This is our CTO Thomas from the US who manages our web properties that include this website, Good Smile Company, Max Factory, Figma and King Records.

Our Creative Director Zhao from Singapore - also known as Kodomut online. I discovered his talents through his comments that he left on this site - and followed links to his website where he had a ton of Nendoroid photography. Folks in the office call him Lunch Master or Senpai.

For the moment the lounge space is still quite spacious which would fill up from time to time when we ship Smart Doll.

The lounge by night.

The lounge would also occasionally fill up when the Mirai Frame parts arrive. Straight of of the injection mold, the parts for the frame would be attached to the runner - but leaving them on the runner takes up a ton of space so we break off the parts from the runner and place them in small bags.

This process makes our workflow much more efficient when it comes to assembling the frame.

This process makes our workflow much more efficient when it comes to assembling the frame.

And this is what the frame looks like which we sell as a standalone semi-assembled model.

No plans to sell it as a kit right now as its not consumer friendly - it needs special tools to put together.

No plans to sell it as a kit right now as its not consumer friendly - it needs special tools to put together.

Another one of the reasons why I prefer this side of the office is that its not as bright as the Smart Doll production area which has to be really bright to spot blemishes - I prefer computing work where its a bit darker.

At the moment we have about 200 square meters to grow to the next level. Previously we had only 36 square meters ><

And here is the same view by night.

We moved some of the Smart Doll accessories to this part of the office as this is where we pack and ship.

Same angle by night.

This is the last corner view of the lounge ^^

All staff members are required to knock off at 6PM and everybody is usually gone by 6.30. I stay behind with wifey a wee bit though. Even though our company is located in Japan, we will continue to keep this company culture of allowing employees time to develop, grow and relax in their own free time.

The top of this IKEA KALLAX used to be lined with Smart Dolls but we decided this would be the best place for the TV which was where the sofa is now.

We use the TV for games or meetings using the Apple AirDisplay function which mirrors or extends a Mac's display.

We use the TV for games or meetings using the Apple AirDisplay function which mirrors or extends a Mac's display.

First World problems - the Oculus is a pain to store as its got a ton of wires which need to be attached to a computer through the Display Port and USB *and* have external power. Picked up this clear "Head Bank" from Amazon which is supposed to be used as a piggy bank - its great as it can hold the Oculus unit and the wires too and costs only 1600 yen. As for what the oculus is currently being used for...

This is the "entrance" to the Smart Doll production studio. The empty tables on the left are used for packing and shipping.

After more optimization of the layout, we managed to make more room for new staff while maintaining enough space for our current team to be comfortable during work.

The two new staff members who I hired from the previous Photowalk now sit at the glass tables.

My wife manages finance, HR and anything that involves contracts - none of her main work is customer facing so some folks may find it hard to appreciate the type of work that she does. Without her however, the company would most certainly fall apart ><

Eiji Seiun is going to be the next Smart Doll - the 3D printing, silicon clone to wax and half of the production molds have already been created.

We should get the first look at him in full vinyl towards the end of this month.

We should get the first look at him in full vinyl towards the end of this month.

While there are only a couple of anime licenses that I would want to make (namely Yagami Light and Solid Snake), there are a load of Marvel heroes that I would pursue later on this year. Which Marvel or DC hero would you like to see as a Smart Doll?

I spend a lot of my time optimizing furniture, stock and other bits n pieces around the office. Having an organized office is key for daily operations as it minimizes the time needed to find and get to stuff.

Moving Smart Doll accessories near to the packing tables was just a no-brainer example.

The injection molding of the frames for Smart Doll is mostly done in Yamagata Shinjo. The slush molding of the outer shell (skin part also called "Gaihi" ) is all done in Katsushika Tokyo.

All the parts arrive in the office where we need to perform quality control and then assemble which involves cutting flash, sanding the surface etc.

Unlike many startups who feel they need to splurge out on expensive furniture to lure potential candidates, I choose to continue to go with IKEA as the price is certainly economical for very acceptable furniture quality.

These plastic containers are also from IKEA and are essential for our daily production - not sure what I would do without them ><

We use them for everything including keeping stock, sorting and storage.

We use them for everything including keeping stock, sorting and storage.

Most items are stored in bags of 50 before they are placed in their containers. This means that when we do our regular stock taking, instead of counting everything in a container (200 pieces for example), we can count 4 bags which contain 50 pieces each.

The white boxes on the top of each table are cardboard "heat boxes" with a hole cut in the top where a ceramic heater is placed.

The heater then heats the inside of the box where outer shell is placed before flash is cut or when we assemble the Smart Doll.

The white arms fixed to the tables are magnifying glasses that have a built in LED which I picked up from Amazon. Each Table also has a Z Light to provide extra light which we shine at an angle across the parts to check for scratches and other blemishes.

Over 80% of our work involves checking parts and accessories for blemishes - depending on the severity, I will approve them as long as it does not affect the overall appearance of our products.

Kizuna and Mirai wearing some of our Bridal Collection which launches this month.

This is the worst part about dealing with products - the boxes which take up a huge amount of space ><

Some electronics stuff going on in the lounge.

Some Smart Doll customers kept asking about painted busts - I originally had no plans to make any but decided to put resources into it and found out that they were more sought after than I thought they would be.

Each bust part has to be primed with matte top coat which then allows the 3 different shades of ground pastel to stick to the surface. We then spray 2 layers of top coat again on top to keep everything in. Not only are the headlights painted but also very slightly around the back, side of the oppai and collar bone too.

Last month we started to sell the painted busts in large size, this month we will start to sell the medium sized ones.

While the main chunk of our current business is Smart Doll - you don't really need to be interested in dolls to work for us - you need to understand what they are, how they are made and what our customer demographic is though.

The first task for our TV Producer is to work on a commercial for Smart Doll.

Got a new toy for filming - the KONOVA Camera Slider K5 100 cm. Our heavy duty Libec RS-250M video camera tripod lets us use the K5 with only one set of legs without stability issues.

Zhao together with our talent all-rounder fashion designer working on hijab designs for Smart Doll.

We recently got some equipment for prototype and production of small quantities of apparel items - the JUKI TL-Y10SP sewing machine and a JUKI MO-114DM overlock machine.

The hijab will be made in our office and released this month in two colors - red and dark brown. Both come with a long sleeve turtle neck too.

Folks who handle dolls wrap cushioning sponge around their Z lights - this is to prevent damage to the dolls during inspection as they previously hit the corner of the light ><

We have been working hard to ship as many Mirai and Kizuna as possible but still have a large backlog of pre-orders. The backlog will start to clear out as soon as we have sorted out issues that were introduced when we made the Mass Production molds.

If you are still waiting for your Smart Doll then please accept my apologies ><

If you are still waiting for your Smart Doll then please accept my apologies ><

No shoes in the office - if you are visiting then please take them off. The only other company that I know that does not allow shoes inside the office is Good Smile Company.

Our entrance now decorated with posters of Mirai, Kizuna and Chitose.

And here is an overview of our office.