About Culture Japan

This post gives an overview of what our company does, job descriptions, a drill down on Smart Doll (the lion's share of revenue) production and details of how folks can work for us when there are openings.

What is Culture Japan?

Established by Danny Choo, Culture Japan is an umbrella brand formed under the company Mirai Kabushiki Gaisha - the brand is associated with our 3 consumer facing businesses which are TV Production, Character Development and the manufacture of a 60cm (23.6 inches) tall fashion doll called Smart Doll.

We also develop a Content Management System called Mirai Gaia which is being used to run dannychoo.com and is also used for our B2B business by clients such as Good Smile Company, Max Factory, King Records, KONAMI and KADOKAWA.

Company Outline

Registered Company Name MIRAI Kabushiki Gaisha

Established 2007

Capital 5 Million Yen

President Danny Choo (full profile lives here)

Office Location Shinagawa-Ku, Nishi Gotanda, Tokyo, Japan

Clients Japanese Cabinet Secretariat, Japanese Ministry of Economy Trade and Industry, Japanese Ministry of Land Infrastructure Transport and Tourism, KONAMI, KADOKAWA, Sony Computer Entertainment, Dentsu, Good Smile Company, Bushiroad, Disney Japan, King Records, Production IG etc.

Established 2007

Capital 5 Million Yen

President Danny Choo (full profile lives here)

Office Location Shinagawa-Ku, Nishi Gotanda, Tokyo, Japan

Clients Japanese Cabinet Secretariat, Japanese Ministry of Economy Trade and Industry, Japanese Ministry of Land Infrastructure Transport and Tourism, KONAMI, KADOKAWA, Sony Computer Entertainment, Dentsu, Good Smile Company, Bushiroad, Disney Japan, King Records, Production IG etc.

About Danny Choo (Past)

After I discovered Japanese Culture in the early 90's back in the UK through Japanese console games, I developed a passion to live and work in Japan. To reach this goal I continued to religiously self study Japanese and took five part time jobs two of which involved carrying, washing and occasionally breaking dishes as a waiter. Exactly how these part time jobs interlinked with each other and got me to Japan are outlined in the How Discovering Japan Changed My Life post.

I arrived in Japan in 1999 and spent 8 years working in the Internet serving as a Marketing Executive at the scientific journal Nature, Website Manager at Amazon and Product Manager at Microsoft.

During my corporate years, I learned how to program PHP and MYSQL from Google Sensei and began moonlighting where I made websites outside of work which eventually lead me to leave Microsoft to start my own gig. My annual income went from 300,000 USD to 0 USD after making the leap out of the comfort zone.

I started to deplete my savings and stock options from corporate days as it started to dawn on me that companies began to think that it wasnt worth paying big money for a website when they could do what they need with social media like Twitter.

I ran around Tokyo with mockups and gave more presentations on Mirai Gaia only to be told "We shall consider your product positively" which in Japanese means "Get Lost." I also remember giving a presentation where the president actually fell asleep (true story).

Eventually, a figure company called Good Smile Company decided to give Mirai Gaia a whirl after I offered to make their corporate website in exchange for figures instead of money. With a brand like Good Smile Company on my portfolio, getting paying clients onto the platform became slightly easier.

Back then I had a well known blog about Japanese culture and a few clients under the belt but always felt that I didn't accomplish much more than that. What I could charge for web development barely made enough to pay for the servers and wages. For many years I would peer into the windows of other offices filled with warm bodies thinking about when I would be able to turn this company around to make it self sustainable and profitable.

I also made a few hiring mistakes in the early days of the company and would lie to myself saying that these folks were worth keeping. The fact was that I was scared I would not be able to go it alone if I let them go and would rather have them on board even if they didn't do much apart from browsing Flickr all day long - I had many arguments with wifey about this and we nearly sold our house to keep the company going.

I decided to use pretty much all of our savings (while managing to keep the house) and bet on a product that I believe would change everything for us - and it did.

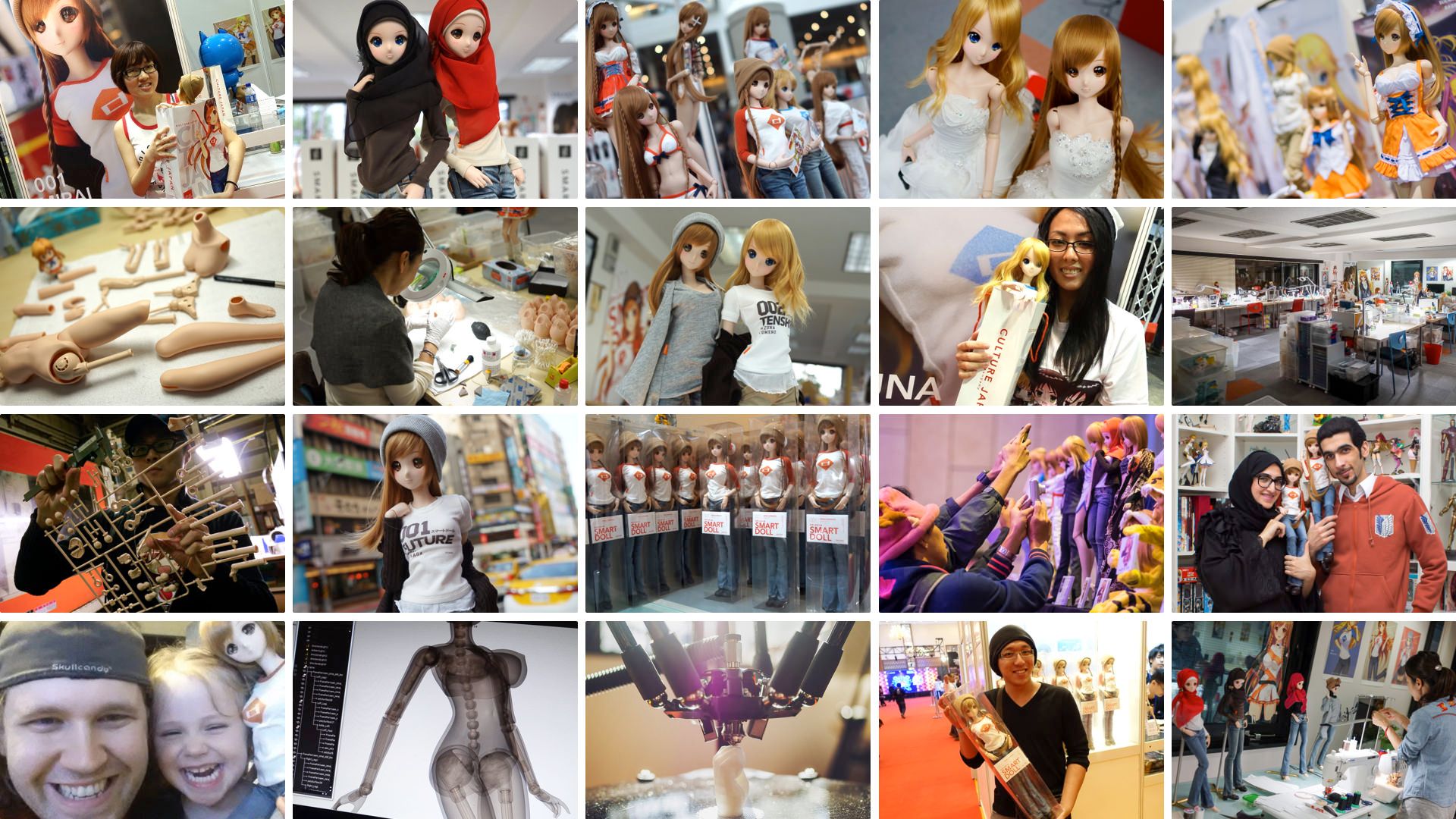

In June 2014, we released Smart Doll - a 60cm tall fashion that I modeled after my mascot character Mirai Suenaga.

In June 2014, we released Smart Doll - a 60cm tall fashion that I modeled after my mascot character Mirai Suenaga.

The How I started My Company in Japan post covers some more detail of how we came to be at our current stage in the company.

About Danny Choo (Present)

Even though my company was incorporated back in 2007, I've never felt like I was in a startup until now - it's like Day One all over again but different this time. I've bootstrapped the company to a point where its self sustainable and now spend my time trying to solve an entirely new set of problems which mainly deal with management of the supply chain (vendors, logistics, storage, order purchasing, inventory) while working out how to scale production to meet demand and stay lean.

We will continue to grow on our own cash and have been doing so at a rate that I myself find overwhelming at times considering it took so long to get here. We don't have ample cash flow which I think is good at this stage in the company as it forces us to innovate our workflows and prioritize our time and resources on the big and impacting rather than the small and insignificant.

I thought that when we launched Smart Doll that I would aim to produce about 50 units per month which seemed like a doable goal given that the production line was still in its infancy with a plethora of quality control issues. I completely underestimated the demand and now we have already shipped a few thousand units in under a year.

In the midst of wanting things done immediately, I began to realize that a founder of any company would want their startup to grow faster and also want things done straight away but in order to go faster, it's important to slow down from time to time to not only reflect on what's going on but also to take time out to make sure the foundations are strong before building more on top.

There are so many companies out there who grow fast but also fail fast because they didn't slow down to fix and reflect - just imagine building a house on top of foundations where the concrete wasn't completely cured - you would finish the house quicker but the consequences of an incomplete foundation could also affect the lifespan of the house too.

Soon we gain the ability to ship 1000 units per month and by then would have worked out a template that we can copy and paste to increase production - I believe that it's only a matter of time when Smart Doll becomes the world's standard fashion doll.

We have just recently outgrown our new office in Gotanda Tokyo. I thought that the 200 square meters would last maybe 2 years but only lasted 9 months. Luckily the folks on the 1st floor of our building moved out which I acquired to make into a fulfillment department and retail store.

Apart from running the company, I also work with the Japanese government who appointed me to be on various committees which revolve around the dissemination of what they call "Cool Japan" which you can read more about here.

Folks who are interested can connect on my social networks.

- facebook.com/dannychoodotcom (385k likes)

- twitter.com/dannychoo (101k followers)

- instagram.com/dannychoo/ (32k followers)

- youtube.com/tokyostormtrooper (105k subscribers)

- LINE (3 million likes)

- PSN Profile (add me anytime!)

TV Production - Culture Japan & Japan Mode

I direct and present on a TV show called Culture Japan which covers Japanese Pop and Traditional culture.

The show is broadcast on Tokyo MX TV in Japan and across the world on various cable, terrestrial and online networks including Animax Asia, Mnet in America and Crunchyroll. Culture Japan is viewable by 67,909,933 households worldwide (not including online viewers).

The show is broadcast on Tokyo MX TV in Japan and across the world on various cable, terrestrial and online networks including Animax Asia, Mnet in America and Crunchyroll. Culture Japan is viewable by 67,909,933 households worldwide (not including online viewers).

While Culture Japan is targeted at folks outside of Japan, the national broadcast in Japan became particularly popular in its second season often trending on Twitter after each episode.

I also present on a TV show called Japan Mode which focuses on Japanese lifestyle. Japan Mode is broadcast on FOX's Star World channel across Asia and is sponsored by Panasonic and Toyota.

Character Development - Mirai Suenaga

Back in 2007, I created a character who I named Mirai Suenaga - the meaning is "Eternal Future." Her name is pronounced "mee-rai soo-eh-na-ga."

Back then she was created with the purpose to prettify the website but she ended up becoming more than a website mascot. Mirai went on to collaborate with various anime and game companies such as Square Enix, Good Smile Company, Bushiroad, Ascii Media Works, King Records, Nitroplus and the convenience store LAWSON.

Back then she was created with the purpose to prettify the website but she ended up becoming more than a website mascot. Mirai went on to collaborate with various anime and game companies such as Square Enix, Good Smile Company, Bushiroad, Ascii Media Works, King Records, Nitroplus and the convenience store LAWSON.

In 2013, Mirai became an official mascot for Japan Tourism and in 2014 she became an official mascot for Malaysia Tourism.

In April 2015, Mirai starred in her first live action drama doS Deka (Tabe Mikako, Yoshida Yo) which was broadcast on NTV in Japan. This first episode reached a record high 12.7% viewership across Japan beating even some of the most popular anime titles.

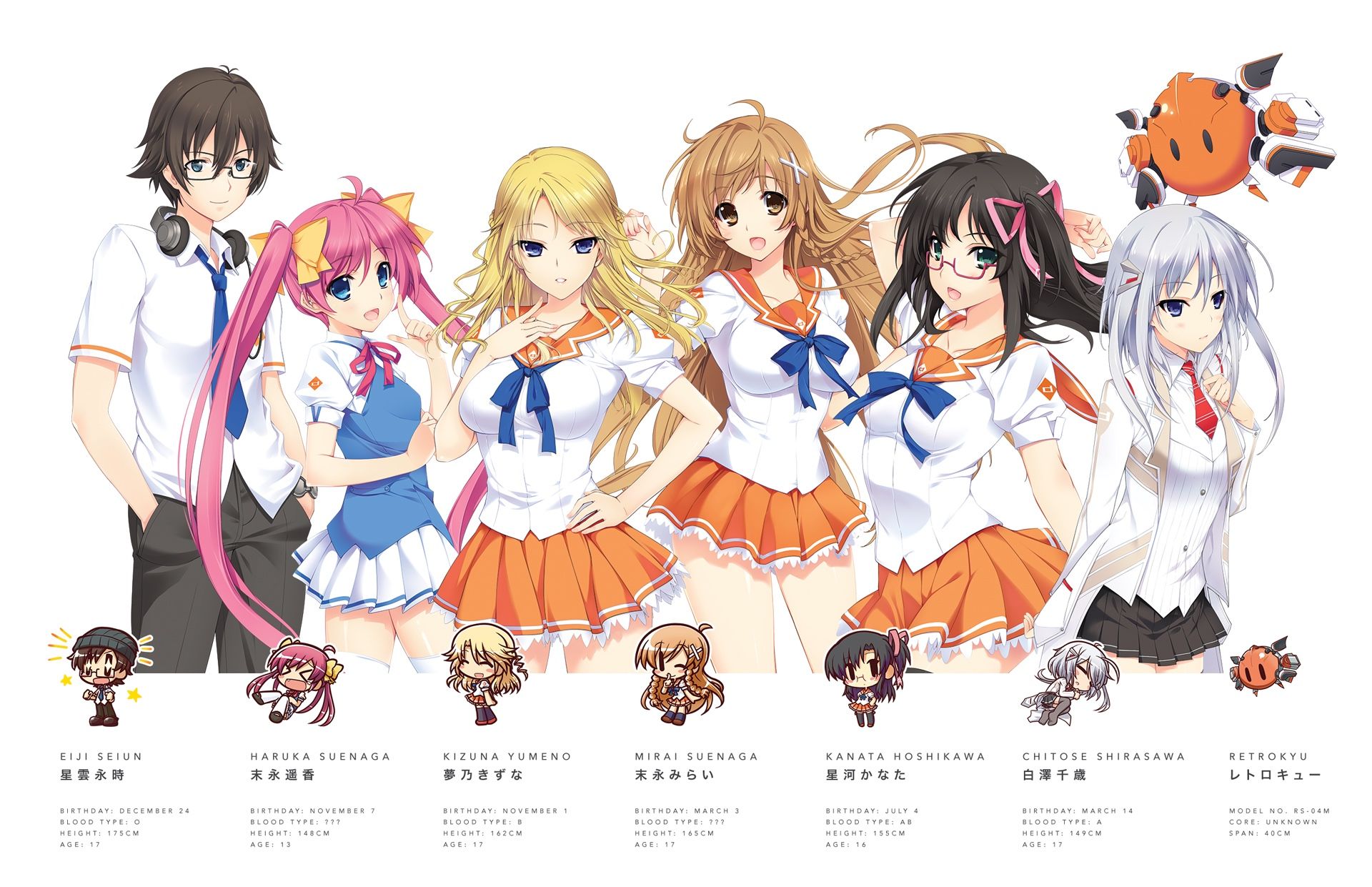

Character Development - Mirai & Friends

Somewhere along the way, I created more characters to keep Mirai company - her younger sister Haruka Suenaga, a floating spherical robot called Retrokyu and 4 school mates who are Kanata Hoshikawa, Eiji Seiun, Kizuna Yumeno and Chitose Shirasawa.

All of our characters are also the heroines (and hero) of a story called "Mirai Millennium" - a story written by established Japanese writer Sato Dai who also wrote the scenario for titles such as Cowboy Bebop, Ghost in the Shell SAC, Eden of the East, Eureka Seven and more. The story Mirai Millennium is yet to be released.

All of our characters are also the heroines (and hero) of a story called "Mirai Millennium" - a story written by established Japanese writer Sato Dai who also wrote the scenario for titles such as Cowboy Bebop, Ghost in the Shell SAC, Eden of the East, Eureka Seven and more. The story Mirai Millennium is yet to be released.

Learn more about Mirai & Friends >

"Mirai" means "Future" in Japanese and that's what she turned out to be for me and my company - everything that we do revolves around her.

As mentioned earlier on, Mirai was created to prettify my website and not originally created with monetization purposes. For this reason, unlike traditional character licensing business models, I built Mirai's brand using a different approach where the involvement of her in various collaborations is free.

Through this approach, Mirai Suenaga over the years grew a large fanbase worldwide with a particularly strong following in Malaysia, Indonesia and the Philippines.

Through this approach, Mirai Suenaga over the years grew a large fanbase worldwide with a particularly strong following in Malaysia, Indonesia and the Philippines.

As for derivative works - we encourage folks to monetise from their creative works of Mirai and Friends - no need to ask us for permission and no need to pay us anything either - we will never go after creators like anime publishers do from time to time. Any work we feel is outstanding will be shared with our fans through Facebook/Twitter etc so that they can buy your stuff.

Product Development - Smart Doll

Smart Doll is a line of 1/3 scale (60cm tall) articulated fashion dolls that I designed with the help of Google Sensei and 3D rapid prototyping techniques which enabled me to get from blank canvas to market in under 2 years. I did spend 2 years prior to that on research however until 3D printers started to become available for consumers at which point I realized that I could model the sculpt in house instead of looking for a traditional sculptor.

The Smart Doll product is a fusion of art and both modern and traditional molding methods which enables us to create a stylish and fashionable line of fashion dolls for an international market.

The “SM” from “SMART” means “Social Media” while the rest means “ART.”

Smart Doll is art which connects people in ways that an online social media service cannot possibly do in an offline world.

The “SM” from “SMART” means “Social Media” while the rest means “ART.”

Smart Doll is art which connects people in ways that an online social media service cannot possibly do in an offline world.

The following video is an overview of what we do for Smart Doll production.

Our Customers

Smart Doll is designed for all races, ages and genders. Our customers are from all walks of life from a variety of backgrounds. Owners are notably creative who love to customize and take photos of their Smart Doll.

So far we have shipped Smart Doll to thousands of customers in 42 countries around the world which are the United States, Japan, Taiwan, Hong Kong, Malaysia, Canada, Singapore, Australia, France, China, United Kingdom, Germany, Thailand, Indonesia, Russia, Belgium, Qatar, South Korea, Philippines, Denmark, Spain, Brazil, Netherlands, Kuwait, Finland, Mexico, United Arab Emirates, New Zealand, Norway, Saudi Arabia, Mauritius, South Africa, Panama, Brunei, Poland, Italy, Hungary, Switzerland, Peru, Jordan, Uruguay and Vietnam.

You can see some of our customers photos on the Smart Doll Pinterest Board which we look for on Social Media using the tag #SmartDoll.

Jobs

Below is a list of job descriptions which should give you a better understanding of what we do. When there are openings, I usually announce them on my Twitter account together with an application period and method.

Video Production

Both Culture Japan and Japan Mode are produced in house using our own video, sound and lighting equipment. Our editing is done on either Final Cut Pro or Adobe Premiere on Macs.

Members who work on video production have a good understanding of Japanese in order to be able to cut high level business conversations.

Team members also write scenarios and plan out camera angles/lighting/timecode and focal lengths for each shot in the scenario prior to a shoot.

Both Culture Japan and Japan Mode are produced in house using our own video, sound and lighting equipment. Our editing is done on either Final Cut Pro or Adobe Premiere on Macs.

Members who work on video production have a good understanding of Japanese in order to be able to cut high level business conversations.

Team members also write scenarios and plan out camera angles/lighting/timecode and focal lengths for each shot in the scenario prior to a shoot.

Graphic Design

Graphic Design work at Culture Japan involves compositing creatives of posters, product packaging, vehicle wraps, collaboration items such as IC cards, merchandise, blueprints etc of our characters, visuals for booths and events using tools such as Photoshop, Illustrator, InDesign and so on.

Graphic Design work at Culture Japan involves compositing creatives of posters, product packaging, vehicle wraps, collaboration items such as IC cards, merchandise, blueprints etc of our characters, visuals for booths and events using tools such as Photoshop, Illustrator, InDesign and so on.

This team keeps themselves in the loop with trends in social media, design, typography and uses this awareness together with their graphical skills and knowledge to not only build on the branding for our content and products, but to also create visuals while learning from previous designs and their conversion rates.

Our design work also involves forecasting layouts and typefaces which will still look good in at least 1 years time. Before we implemented this workflow, we found that all our designs became stale within 6 months.

Graphic Design members also have a good understanding of Japanese which is required to work with partners and to understand the text and font that they are working with.

Event Strategy

We attend and run our own events worldwide to not only promote our brand but also meet and network with fans in each region.

This team works on rolling out events which involves management of purchase orders, logistics/storage/import procedures of merchandise, local tax laws, forecasting sales so that we don't over or understock, work with local teams on marketing and translation of blurb required for the event and the actual layout of the booth itself.

We attend and run our own events worldwide to not only promote our brand but also meet and network with fans in each region.

This team works on rolling out events which involves management of purchase orders, logistics/storage/import procedures of merchandise, local tax laws, forecasting sales so that we don't over or understock, work with local teams on marketing and translation of blurb required for the event and the actual layout of the booth itself.

Booth mockups are all done in Sketchup and need to be designed considering construction costs, layout of hall and flow of traffic, sound from surrounding booths and visibility of visuals from different angles, heights and distances from the booth. Menu's need to be designed considering language, exchange rates and conversion rate data taken from previous events.

Everything else from queue control, security, number of tills, spare change, rubber bands etc also need to be procured and prepared.

Web Development

To support our online branding and content dissemination, we have created our own proprietary CMS called Mirai Gaia. Mirai Gaia previously was built by myself on PHP and MYSQL which ran dannychoo.com on a single server.

Today, Mirai Gaia has migrated to Ruby and recently moved from EngineYard to Amazon's AWS OpsWorks running several servers with a CDN for image and asset distribution.

To support our online branding and content dissemination, we have created our own proprietary CMS called Mirai Gaia. Mirai Gaia previously was built by myself on PHP and MYSQL which ran dannychoo.com on a single server.

Today, Mirai Gaia has migrated to Ruby and recently moved from EngineYard to Amazon's AWS OpsWorks running several servers with a CDN for image and asset distribution.

We also have developed our own inventory and forecasting web application called Mirai Atlas that is used for managing our Smart Doll business.

Mirai Atlas enables us to make purchase orders and manage inventory in various warehouses which enables us to keep track of what we are spending. The system is also linked to our online and offline sales data which gives us not only a better understanding of what our profits are but also enables us to forecast better too.

Mirai Atlas enables us to make purchase orders and manage inventory in various warehouses which enables us to keep track of what we are spending. The system is also linked to our online and offline sales data which gives us not only a better understanding of what our profits are but also enables us to forecast better too.

Character Development

Character development involves building the brand of our current characters through working with creators, companies and individuals on projects of varying scales.

Character development involves building the brand of our current characters through working with creators, companies and individuals on projects of varying scales.

For example we work with many established artists on illustrations and with government organizations such as Japan Tourism and Malaysia Tourism too.

Smart Doll Production Jobs

Smart Doll production is done in Japan - body frames are injection molded in Yamagata and outer shell parts casted in Katsushika Tokyo. Some apparel and wig items are made in Korea which has a rich BJD (Ball Jointed Doll) culture.

Smart Doll production is exciting because it's our first time doing it. There is so much to learn, invent, build and expand/improve upon.

Smart Doll production is exciting because it's our first time doing it. There is so much to learn, invent, build and expand/improve upon.

The BJD is still a small niche market and it's our job to bring this form of art and inspiration to the rest of the world - and we have been doing so - about 80% of our customers are first time fashion doll owners.

Inventory, Purchase Order Management and Sales Forecasting

They may all sound boring but managing these 3 things is key for any business.

This job also involves managing relationships with vendors who produce components for us and anybody working on this team can expect 80% of their time to be dedicated to maintaining our quality standards.

They may all sound boring but managing these 3 things is key for any business.

This job also involves managing relationships with vendors who produce components for us and anybody working on this team can expect 80% of their time to be dedicated to maintaining our quality standards.

Vendor's are usually great at doing their specialist jobs but the level of quality is set by their clients expectations - for this reason it is always challenging in educating and changing the culture of vendors to work with our high quality requirements.

Smart Doll Production

The Smart Doll production team takes all the components and assembles everything together - but before this is done, parts need to be rechecked (even after QA has gone through them, the flash needs to be cut and a load of other processes need to be complete before the body is ready to be packed.

The Smart Doll production team takes all the components and assembles everything together - but before this is done, parts need to be rechecked (even after QA has gone through them, the flash needs to be cut and a load of other processes need to be complete before the body is ready to be packed.

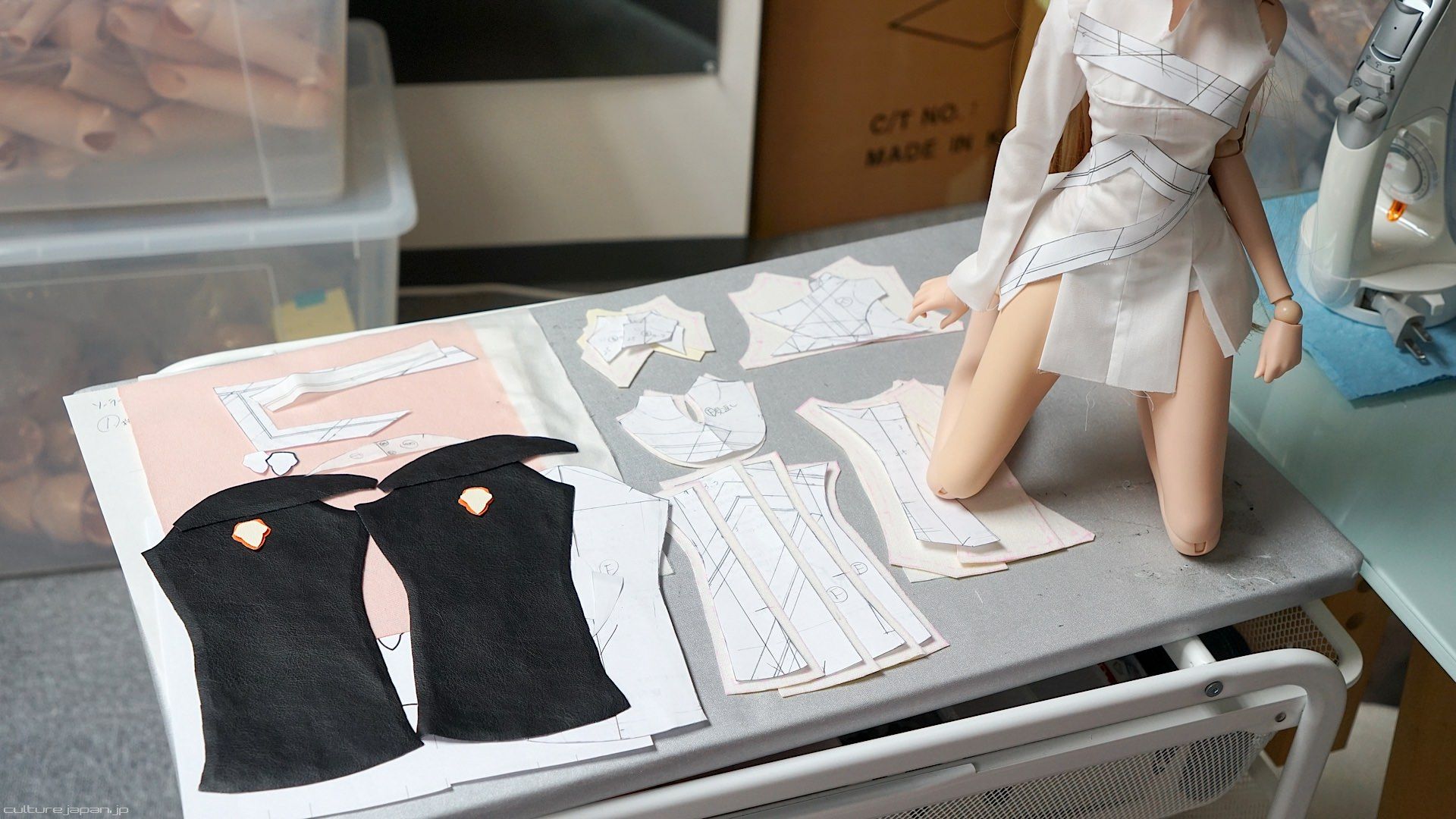

Apparel Development

While there are many doll seamstresses out there who can produce high quality apparel in small quantities, there are not many places in the world that are able to mass produce miniature clothes at high quality.

While there are many doll seamstresses out there who can produce high quality apparel in small quantities, there are not many places in the world that are able to mass produce miniature clothes at high quality.

In order to speed up the concept > market ready process, one of my goals is to increase headcount of our apparel team in Tokyo and setup apparel studios in various locations across Japan

Licensing

Smart Doll is the perfect platform for character license development for anime, games and Hollywood movies too. In the very near future we plan to start making Smart Doll's of various characters and will be needing folks to manage not only the licensing agreements and supervision of prototypes at each stage by the licence holder, but also manage the production that will be involved in recreating the visual look and feel of the character in miniature form.

Smart Doll is the perfect platform for character license development for anime, games and Hollywood movies too. In the very near future we plan to start making Smart Doll's of various characters and will be needing folks to manage not only the licensing agreements and supervision of prototypes at each stage by the licence holder, but also manage the production that will be involved in recreating the visual look and feel of the character in miniature form.

Product Development

Product development is also done in our Tokyo offices. Together with our own 3D modeling team and 3D printers, we rely heavily on 3D rapid prototyping techniques to get our products to market within short cycles.

Product development is also done in our Tokyo offices. Together with our own 3D modeling team and 3D printers, we rely heavily on 3D rapid prototyping techniques to get our products to market within short cycles.

After prototype creation, this team then has to work out how and where the product is going to be mass produced, how it will be QC'ed, what the packaging will look like and how its made etc.

This team is also responsible for things like creating slush or injection molds, procuring components and material, creating paint masks for the faceup (painting of the face), development of the eyes which involves considering ink saturation and how light is bent through the acrylic depending on the eye radius and distance of print from eye surface etc.

Quality Control

80% of our time is taken up by Quality Control. All components that arrive in our office in Tokyo are checked and where possible we try to fix anything that can be done in house - if not we send them back to the vendors and give them a spanking.

80% of our time is taken up by Quality Control. All components that arrive in our office in Tokyo are checked and where possible we try to fix anything that can be done in house - if not we send them back to the vendors and give them a spanking.

**Fulfillment & Customer Service **

At the moment most of our orders are taken online using Shopify and sometimes folks come to the office to pick up. As we are still new to all of this, much of this process is still very manual and involves printing picking lists, invoices, packing slips and so on.

At the moment most of our orders are taken online using Shopify and sometimes folks come to the office to pick up. As we are still new to all of this, much of this process is still very manual and involves printing picking lists, invoices, packing slips and so on.

Up until recently we used shared email to manage customer queries which was a nightmare but now we are using Zendesk which enables us to collaboratively manage customer queries and keep our sanity at the same time.

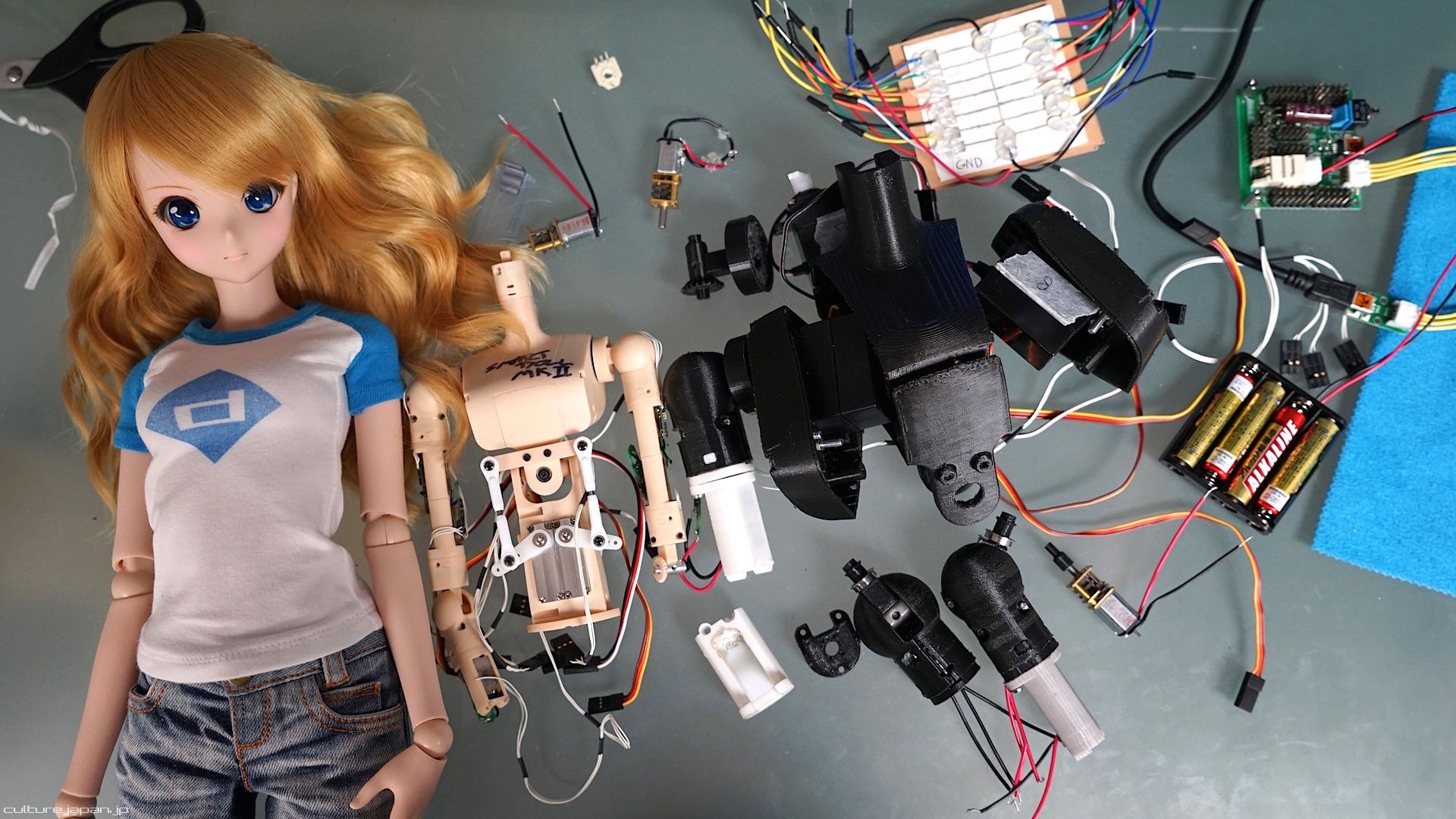

Robotics

The Automated version of Smart Doll is now known as Smart Doll Plus. Robotics development is a prohibitively expensive - we could easily spend all our cash flow on its production but fortunately have more sense than money so we focus on the "Manual" version which is already on the market and generating a self sustainable business for us.

The Automated version of Smart Doll is now known as Smart Doll Plus. Robotics development is a prohibitively expensive - we could easily spend all our cash flow on its production but fortunately have more sense than money so we focus on the "Manual" version which is already on the market and generating a self sustainable business for us.

Having said that, I do spend resources working on this as a side project and will complete it.

3D Engineering

Our 3D Engineers are equipped with skills to use a variety of 3D software such as ZBrush, SolidWorks, Autocad, Rhinoceros, 3D Max, Maya etc and are fully versed in issues relating to preparing the data for machining molds or for the printers we use in the office.

Our engineers have a good understanding about the various types of manufacture and material properties which enables them to design while taking into account various factors such as injection molding slide, ejector pin, warpage, shrinkage issues etc.

Our 3D Engineers are equipped with skills to use a variety of 3D software such as ZBrush, SolidWorks, Autocad, Rhinoceros, 3D Max, Maya etc and are fully versed in issues relating to preparing the data for machining molds or for the printers we use in the office.

Our engineers have a good understanding about the various types of manufacture and material properties which enables them to design while taking into account various factors such as injection molding slide, ejector pin, warpage, shrinkage issues etc.

Working at Culture Japan

A typical Japanese company requires a resume (using the standard Japanese format with photo attached). Apparently the way you look says a lot about your abilities.

As a hiring manager at Amazon, I never ever looked at school qualifications on a resume and only barely skimmed through the work experience section.

This is not to say that I don't think qualifications are important - they are if you plan to work for pretty much any other company that requires a resume and having a sharp resume format will probably help too.

To work for us however, I don't care about the claims candidates make on paper, about what they have done in the past, I don't care what age or race they are and I don't care about what they look like. What I do care about is what they can do for us right now.

To work for us however, I don't care about the claims candidates make on paper, about what they have done in the past, I don't care what age or race they are and I don't care about what they look like. What I do care about is what they can do for us right now.

I always encourage folks to make time for side projects to learn stuff - it doesn't matter if you are a student or salary wo/man - its something you should do. If you can make time for sleep, food, poo and checking Facebook then you got time for side projects - the particular ones that I'm on the look out for is things like illustrations, apps and physical creative stuff like cosplay, kitbashes and so on.

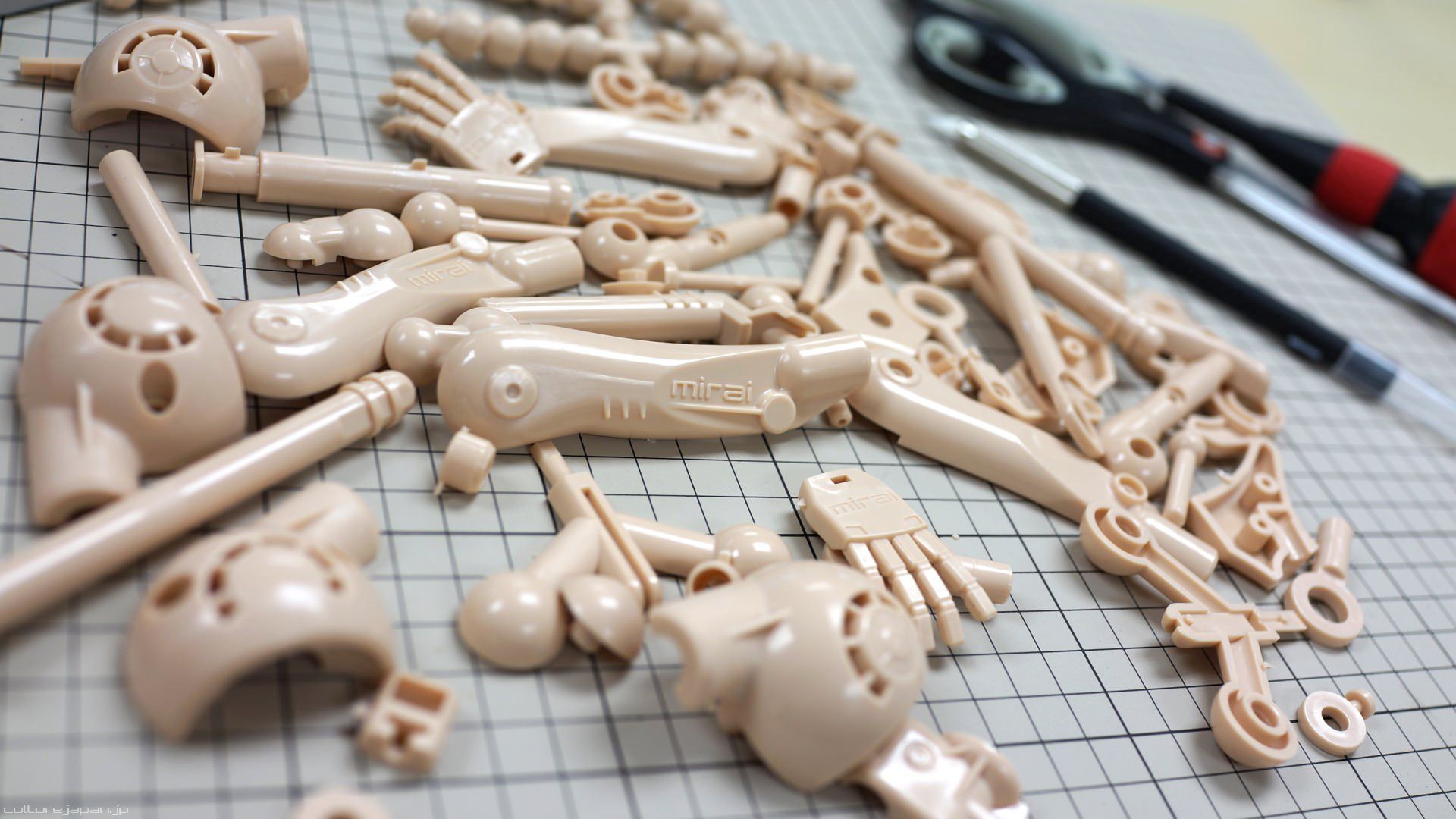

Our Entrance Examination

Folks who are creative and like making stuff are most suited to the company culture here at Culture Japan. For this reason, everybody we hire has to pass a single test called the "Mirai Frame Challenge" - regardless of the position that they are applying for.

"Working with ambiguity" was a requirement during my days at Amazon and this requirement lives on at Culture Japan. Candidates need to be able to achieve without specific instructions. Not only does the "Mirai Frame Challenge" test ones ability to make stuff but also one's ability to work with ambiguity as we do not include written instructions to make Mirai Frame. This test also adds the element of dexterity as we need folks to be nimble too.

Some may say that this test is a lousy measure for somebody applying for a marketing position. I will tell you why this is not so for our company.

During my time at Amazon, all senior members including Vice Presidents had to participate from time to time in Customer Connection programs which had them working for a few days at places like the Fulfilment Centers or Customer Service which keeps them in touch with the customer.

During my time at Amazon, all senior members including Vice Presidents had to participate from time to time in Customer Connection programs which had them working for a few days at places like the Fulfilment Centers or Customer Service which keeps them in touch with the customer.

At Culture Japan, everybody needs to fully understand the product and the amount of work that goes into creating it. This means that departments (like marketing) who are not directly involved with production can make better judgement calls in their job through the experience of actually creating the key component for our products.

Mirai Frame Challenge

The challenge is to build Mirai Frame within 1 hour and at the moment the challenges are done at our offices in Tokyo. There are no instructions and candidates need to work out how to build it by looking at the completed samples that we provide.

We give folks 2 hours to complete their first Mirai Frame, 1 hour to complete their second one and their third one should also be completed in 1 hour - a total of 4 hours.

At the end of each round, the judge examines each frame to make sure everything is in the right place and that joints are not too loose or too tight. If candidates can complete the first frame in 2 hours, we point out any mistakes made in the first frame and expect the second frame to be made with zero mistakes.

Folks who can't complete their first frame in two hours have the option of leaving or plugging on like a good soldier - but even if they do complete the frame, they do not qualify to be hired. Its like the Hunger Games but folks get to leave alive.

Veteran Gunpla builders have managed to complete their first frame in 30 mins!

Veteran Gunpla builders have managed to complete their first frame in 30 mins!

Candidates who do manage to pass the Mirai Frame Challenge are pretty much hired straight away if they are applying to work on Smart Doll production.

Candidates are not paid to take the challenge - the candidate invests their time while we invest our time and resources and cost of materials and frames - frames made during a challenge cannot be sold as they will usually have some sort or mistake or damage which is expected for a first timer. I must also mention that candidates can only take the test once.

Some folks can build a 1 frame an hour - some can build 2 and is only fair that folks who build faster should be compensated more. Salary is discussed at time of hiring.

Folks who think that doing tests for free is a no no should read about the things I done for free to build my career.

Here are the parts of Mirai Frame - I can't remember how many pieces but I designed it to be built with ease with as least screws as possible. Its made of POM (Polyoxymethylene) which is recognized for its high strength, hardness and rigidity. In this photo you can see that there is still flash left over from the pieces being snapped from the gates. When the frames arrive at the office, we pull off the parts from the runners and place all the pieces in bags to optimize our workflow.

This photo was taken at a recent Mirai Frame Challenge - we did this on a Friday - 3 of them who completed the challenge started to work for us the following Monday.

Folks who think they will be wanting to take the Mirai Frame Challenge should watch the following orientation video on how to complete the whole frame. I made this video because doing the orientation took time. Now we expect folks to watch this video before coming into the office to take the challenge.

As our business grows, we will have the need to increase our production staff and I will announce openings on my Twitter so keep em peeled.

Hiring Policy

This photo was taken during a Mirai Photo Walk - a networking event that I hold from time to time. This one was held last Feb. I got to chit chat with everybody which was great. One of the attendees made a video of the photo walk - he edited the video that night and sent it to me. I liked what I saw and got him to do a few tests. He performed well in some of the tests but not so well in others. I gave him guidance and he persevered through my nit picking feedback.

I recently finished applying for his visa and he now works for us full time as a Video Producer. And yes he also took the Mirai Frame Challenge. I also took on another one of the photo walk participants as a robotics engineer.

I've hired folks in the past who I've never met up until the interview and most of them turned out to be hiring mistakes. During my corporate years I hired a QA person who could not use a mouse and one of my General Managers hired somebody with an MA who was a terrible people manager - so bad that the entire existing marketing team quit.

For this reason, due to the size of our startup, I need to do everything to minimize the chance of making a hiring mistake as I can't afford the time or resources to do so. I need to see folks in action and their output to make a judgement call as to whether they are a good fit for our company culture.

Positions for full and part timers

For now, the biggest area of growth is Smart Doll hands-on production and we will have many openings for full and part timers. Part timers will be focusing on frame building while full timers will be given more responsibilities to work on other production related tasks.

For now, all hires will work in our Tokyo office although we will be opening offices in our key markets around the world probably starting next year.

We hire quite a few students who are either studying Japanese language or taking a university course in Tokyo and our part time positions are ideal to cater for the students schedule. Students do need to be able to come into the office at least 3 times a week for at least 4 hours per day though. Foreign students need to apply for a part time work permit which they can do at the Immigration office at Shinagawa.

Once you start working for us you can go ahead and decorate your desk with Kancolle goodies.

Quality Control

If you read my post on design philosophy, you will know that I factor in a certain degree of Wabi-Sabi so that a correlate amount of imperfection is implemented into the overall look and feel of Smart Doll. But sometimes the outer shell (skin part of the doll) can have too many imperfections which destroys the balance and must be rejected. I would say 80% of our work is doing quality control which rejects about 30% of our parts - sometimes the failure rate can go up to 50% for the heads.

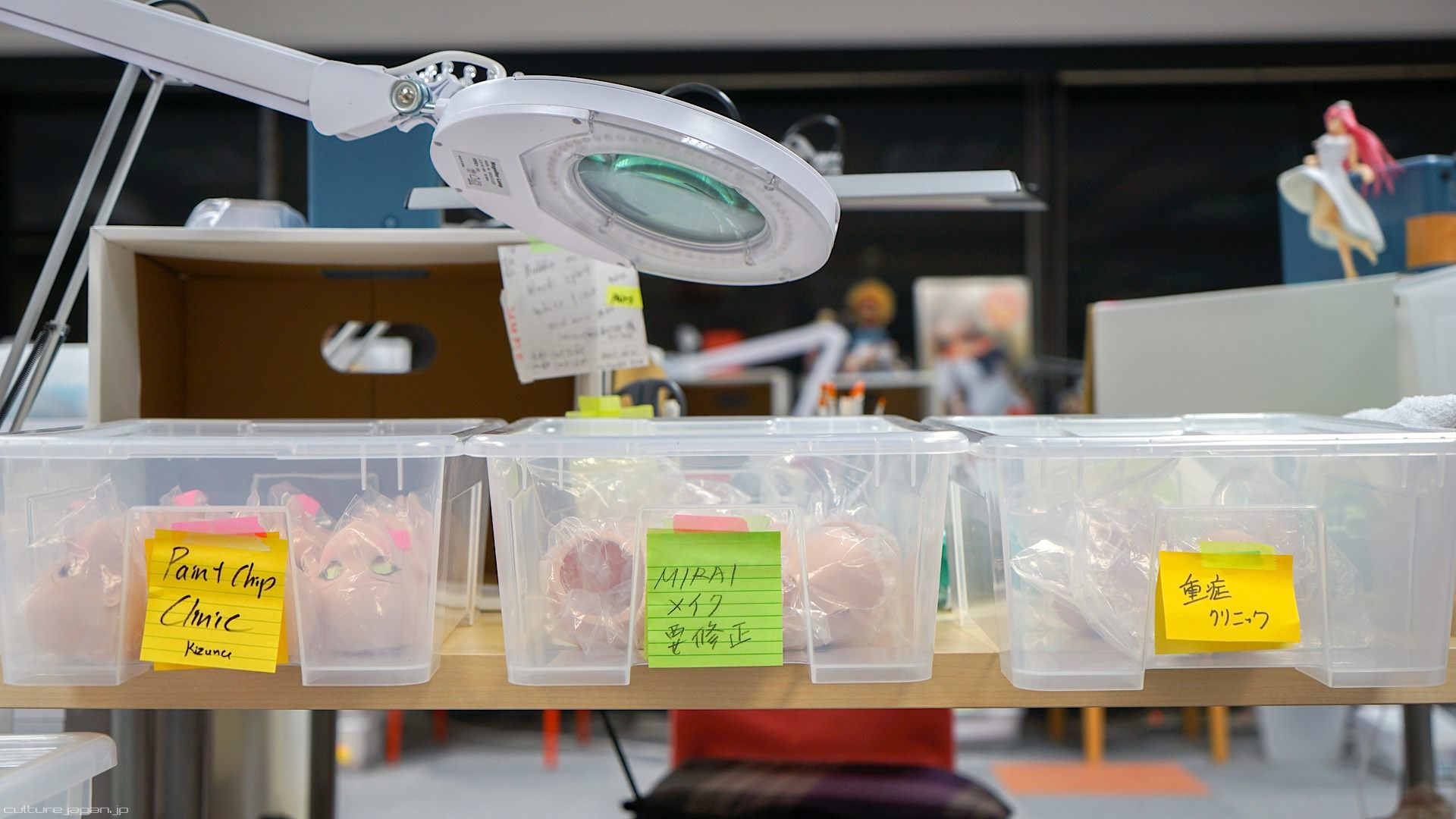

Checking parts requires looking through a high powered magnifying glass with light bounced off the surface at varying angles to spot air pockets, foreign bodies, wrinkles and stretch marks which naturally appear as part of the traditional Slush Casting process. The person checking then makes a judgement call as to whether the Wabi-Sabi level is well balanced or not.

Here is an example of the amount of parts we may reject from a batch of 50 bodies. None of this can be used for products - some we keep to make display and development models for apparel and robotics. Then some need to be disposed of as the quality can turn out quite bad.

All apparel items are also QC'ed which also leaves a bunch of items that we can't sell - just like the pile in the photo.

We don't send all defects back to our vendors for replacement however because as with any type of production, a percentage of failure is expected.

We don't send all defects back to our vendors for replacement however because as with any type of production, a percentage of failure is expected.

Packaging

Anything that a vendor sends us is presumed defective until checked. Apparel items are repackaged in our resealable bags and recorded in our inventory system.

Clinic

We have a "clinic" for the most important component of the body which is the head. The head can be expected to have a correlate amount of Wabi-Sabi - a birthmark below the ear or a faint stretch mark below the chin for example. I can't however approve marks right on the tip of the nose as it will probably be glaring.

When we find defects or injuries in components, we do try to fix them first before giving up on them. Because the head is so important, we can spend up to an hour and a half fixing a single one through processes like sanding, using paint thinner to remove marks and using our painting tools to fix paint chips.

Body Assembly

This is my most fave part of Smart Doll production - assembling and putting the Mirai Frame inside the Outer Shell. It's like seeing my creation come to life! This process is done by using the heat boxes on each workstation - the heatbox heats up the soft vinyl which then enables it to stretch and accommodate the frame.

Flash Cutting

Before the body can be assembled however, unwanted flash must be cut away from the shell part - flash is created when soft vinyl is poured into the slush cast mold. A ninja steady hand is required to cut away the flash with a craft knife - the edge should look like it's been cut by a machine without any pausing as pausing just once will cause a little nick on the edge surface.

This task requires the most precision in the whole assembly process. The person cutting the flash uses the heat boxes to heat up the parts to the appropriate temperature given the thickness of the skin. Too soft and the knife will fly through it like butter - too hard and the knife will get stuck causing a nick mark.

Painting

While faceups of the heads are done in our factory on the other end of Tokyo, painting of the busts are done in our office. Sometimes we need faceups of prototypes which would be done in the office too.

Polishing

The eyes are the soul of our products and have to be crystal clear. Considering that they are made out of acrylic and by nature more dense than resin - the reflective surface is incredibly clear and this is because each eye is polished rigorously with kryptonite (another word for secret formula) before they are inserted into the head.

Fulfillment Preparation

Just before the assembled dolls are handed over to the fulfilment team, the body and head has to be given a dose of quality control again and then contained in these lifesaving IKEA pallets.

Inventory and Space Management

Inventory management is key to our growth - order too much and we are stuck with too much stock and less cash flow - order too less and we can't meet demand.

Location and layout of inventory is important too and is decided when examining workflows and how to optimize them even more.

Location and layout of inventory is important too and is decided when examining workflows and how to optimize them even more.

Apparel development

Apparel development is now done in house by a former fashion stylist. She used to design for humans and now designs for mini humans. Our apparel line for Smart Doll will however develop into a line for humans too.

Apparel is key for our branding which is why I am now focusing resources on creating an apparel studio with more members.

Product Development

Product development is also all done in-house too. We have been doing this for a while now and are quite savvy when it comes to Slush Casting. While the Slush Casting process is slow and manual, the main advantage of Slush is that there are no seam lines like the ones introduced using methods such as Injection Molding.

Here you can see Kizuna wearing the Bio Stream Boots that come with the Solar Marine uniform - prototype printed on our ATOM printer. The next step is to figure out how to make it consumer ready.

Robotics

The robotics folks currently work on Smart Doll Plus - the automated and larger version of Smart Doll. Priority of this project however is much lower than the non robotic version which is reflected in the resources that I allocate to it.

Order Processing & Fulfillment

The fulfillment workflow is still very manual but we are working everyday on evolving it by introducing technology to automate as much of the process as possible.

Folks who do packing are not allowed to do picking to avoid mistakes which implements a second layer of checks.

Packages for overseas are sent by EMS while domestic ones are sent by Japan post. The EMS system provided to us by the local postal service is archaic with no API available at all so we are in the middle of creating our own.

Customer Service

Our company culture is that we focus on the consumer - expectations must be set at all moments in time in regards to quality of product and expected shipping times. We try to deal with email within 24 hours of receipt and in some cases I've spent time with customers on the phone or video chat on skype to remedy problems.

Refunds

We can refund customers in full as long as they contact us anytime before the item has been shipped. Customers are not penalized for cancelling either which I've seen other companies do...

If customers decide to cancel after the product has shipped then they need to cover the costs of the item to be sent back to us and do so within 14 days.

If the item is in the same condition as it was when we shipped it then we will refund customers in full.

If customers decide to cancel after the product has shipped then they need to cover the costs of the item to be sent back to us and do so within 14 days.

If the item is in the same condition as it was when we shipped it then we will refund customers in full.

Why are we proactive in refunds? Because Mirai and Kizuna are lovely girls who need care - frankly we don't want them in the hands of folks who are not going to care about them ^^

So far we have had zero returns but if we eventually do then they will be used as display models and not refurbished and re-sold.

So far we have had zero returns but if we eventually do then they will be used as display models and not refurbished and re-sold.

Warranty

Smart Doll was designed to be sturdy and won't break in normal conditions. Limbs can however break under extreme conditions (falling on the knee on concrete etc). If this happens, we ask customers to contact us with a photo of the injury to asses if they can remedy the problem themselves - if not we will replace the part for free but customers pay for the shipping which is usually cheap because parts can be sent in an EMS envelope - the fee is the lowest price on the EMS tier.

This warranty lasts for 1 year or up to 2 limb injuries - whichever comes first. If customers break something after a year (or break a third limb) then we would generally replace the part anyway as we don't want to see our girls go around with injuries but are not obligated to do so. The warranty only covers limbs and not the torso, bust or head as they do not contain moving parts. The warranty also does not cover stains on the surface of the skin from dark clothing being left on for prolonged periods.

This warranty also covers Smart Dolls purchased from our official retailers and even ones from the second hand market.

No other hobby manufacturer offers a years warranty on a poseable doll due to the support costs involved but if Apple can offer a years warranty on an iPhone that costs around the same price then why should I not be able to offer the same?

Disclaimer

I have quite a few piers in the hobby business in Japan and hear about some of their nightmares of "difficult" customers who purposely break products and contact customer support for hours on end - presumably because they are ronery and got nobody to talk to.

Being a startup, we can't afford to dedicate time to customers like this and if we do encounter any, we would refund the customer in full and ask that the product be returned in any state that its in to cut our losses.

Being a startup, we can't afford to dedicate time to customers like this and if we do encounter any, we would refund the customer in full and ask that the product be returned in any state that its in to cut our losses.

In Store Health Checkup

Customers who visit our stores can get a free health check up on any Smart Doll products that have soul (Mirai, Kizuna, Eiji, Ebony, Chitose etc). Any damaged or loose parts will be replaced or fixed for free.

A Canon store who provide a similar free service would call this "servicing" ^^

Finance

My wife is not only the Ministry of Finance at home but at work too. The finance team will need to grow soon after we implement as much workflow automation as possible.

Each Smart Doll retails for 60000 yen - while this is a competitive price compared to other manufacturers of similar products, the price is a little too high for what I would like it to be.

Our vendors charge high unit costs for the quality that I demand which reflects on the retail price of Smart Doll. However, I believe that cost cutting can also be done in other areas rather than reduce costs through reducing quality.

As a startup, our costs are high because we are still new to the game. But as time progresses, we will generate relationships with more vendors and have more hands on deck to find time to streamline workflows and embrace various technologies that all amount to saving costs which we can then pass on to the consumer.

Another reason why we have high costs is that all body components are made in Japan. Even our boxes and bags are made here too. Speaking with other hobby makers, I hear that they can make stuff in China for 10 times less than what it would cost to make in Japan. At the moment however, I want to continue to manufacture in Japan and take on the challenge to see how far I can reduce my costs.

Work Hard, Play Hard

The most important thing is that employees have fun during work. We have a very relaxed working environment where we expect folks to relax when needed so that they can focus after a refresh. Super Contra still looks so good.

Rest Well

Short power naps are important to keep focused too which is why there is a sofa bed in the office. I would rather have folks lay down to sleep rather than sleep at their desk in a position pretending to be working ^^

And no thats not me on the bed - I'm the only one who is allowed to have one leg over the Mirai dakimakura.

Unlike most Japanese companies who create an atmosphere which makes it difficult to leave anytime before the last train, I fully understand the importance of making sure that employees have their own personal time to wind down or develop their life skills. For this reason, unless there is an emergency, I ask that everybody start packing up to leave at 6PM.

I also find that we are all more focused to finish and complete goals knowing that we have to leave at 6. I personally do stay on a bit though.

I'm aware that folks only have a limited amount of hours at work so this also helps me prioritize what's important for the company.

I find that many companies just think of pointless stuff for their staff to do just because warm bodies are still in the office.

I find that many companies just think of pointless stuff for their staff to do just because warm bodies are still in the office.

On a related note, prime minister Abe was thinking of introducing a system where trains would run all night instead of stopping service at around midnight.

There were concerns that this didn't give rail companies time to give the trains or tracks maintenance - but the main concern was that employees no longer had an excuse to say to their boss - "I'm going home before the last train leaves" meaning that even more people would die from overworking in Japan...

There were concerns that this didn't give rail companies time to give the trains or tracks maintenance - but the main concern was that employees no longer had an excuse to say to their boss - "I'm going home before the last train leaves" meaning that even more people would die from overworking in Japan...

Our business is to continue to bring Japan to the world through our content and products which is why I feel it's important to continue providing opportunities to foreigners (as well as Japanese folks) who add value in terms of language and knowhow of each locale.

As we are still a small company, it's difficult to hire somebody to do a specific role and everybody is expected to be able to take on tasks of varying skills. This prevents the situation in corporate companies where somebody does only one thing. My challenge is to grow the company while trying to keep employees outside the single-task silo.

I'm under no illusion that folks who work for us would want to do so forever. I encourage employees to learn as much as they possibly can on the job while giving the best they can at the same time too. If folks stay on for the long haul then thats great but if folks decide to move on then at least they do so multi-skilled instead of mono-skilled. I also try to use my resources to assist in finding new career opportunities for them too.

I could write a book about the company but need to kinda get on with other stuff ^^

Hopefully this post gives you a better idea of what we do and how to work for us - just remember that sending a resume or hanging around *my house* does not help ^^

Hopefully this post gives you a better idea of what we do and how to work for us - just remember that sending a resume or hanging around *my house* does not help ^^

Waiting times for Smart Doll used to be horrendous - at one point it was about 4 months ><

It's been a year since release and we have learned a lot including how to scale the production line and now the waiting times are now down to 5 - 10 business days for both Mirai and Kizuna when ordering online at get.smartdoll.jp.

Folks who come to our office can pick one up straight away - just contact me at support at smartdoll.jp before you come.

It's been a year since release and we have learned a lot including how to scale the production line and now the waiting times are now down to 5 - 10 business days for both Mirai and Kizuna when ordering online at get.smartdoll.jp.

Folks who come to our office can pick one up straight away - just contact me at support at smartdoll.jp before you come.

Oh by the way - this is our new logo - I bet some of you thought it was a "d" for "danny" ?

The Illustrator file lives here and is free for those of you who want to make stuff.

The Illustrator file lives here and is free for those of you who want to make stuff.